Opportunities

Welding (EN 1090-2 EXC2 / ISO 3834 Standards)

Egesten Met performs steel structure welding in compliance with the EN 1090-2 standard at execution class EXC2 and maintains welding quality control processes according to ISO 3834 requirements. The primary welding method used is MIG. All welding operations follow a Welding Procedure Specification (WPS), based on which a Welding Procedure Qualification Record (WPQR) has been prepared. Every welder is certified according to the EN ISO 9606-1 standard. Visual and, when necessary, non-destructive testing (NDT – such as magnetic particle or ultrasonic testing) ensures weld joint strength and compliance with project documentation.

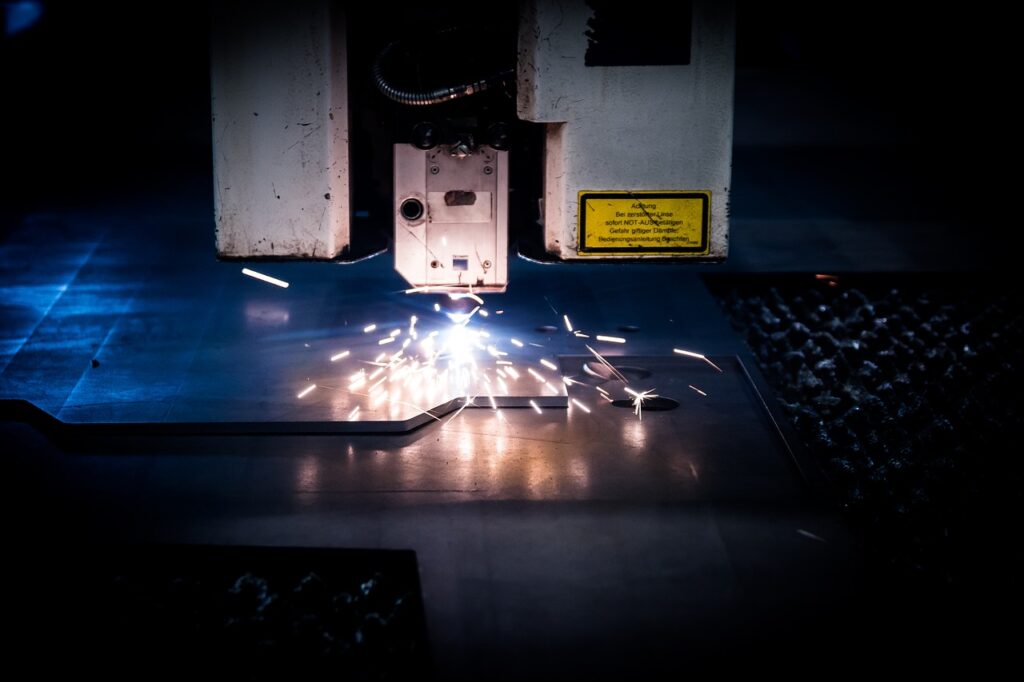

Plasma Cutting (CNC Hypertherm Systems)

CNC plasma cutting is carried out using a high-precision Hypertherm Powermax or similar plasma cutting system, capable of cutting up to 30 mm in black steel and approximately 15 mm in stainless steel. Input files for cutting are provided in .dxf or .dwg CAD format, which are used to optimize sheet usage (nesting) and cutting speed. The plasma cutting process minimizes thermal deformation, enabling clean cuts even for fine contours and holes. Post-cut cleanup (burr-free edges) is performed when needed to prepare components for bending or welding.

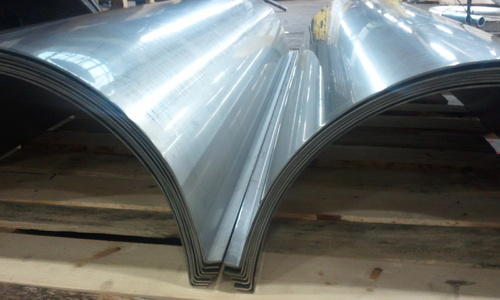

Sheet Metal Bending (CNC Servo Press, 100–160 Tons)

Bending is performed on a CNC-controlled servo press (e.g., Amada, LVD, or Bystronic) with a working width up to 3000 mm and a pressing force of up to 160 tons. The program controls the bending sequence, tool changes, and automatically compensates for material springback. Standardized V- and U-dies are used in combination with custom matrices for bending both straight and angled elements (e.g., U-profiles, boxes, interlocks). The bending radius and working angle are calculated based on material thickness, yield strength, and minimum bending radii (according to DIN standards).

Sheet Cutting (Guillotine / Optionally CNC Laser)

Sheet cutting is done on a hydraulic guillotine shear, suitable for up to 6 mm black steel and 4 mm stainless steel sheets, with a cutting length up to 3 meters. The cutting edge is straight and accurate without significant deformation. Sheets are held in place using pneumatic clamps to prevent shifting during the process. Cutting is based on drawings and can be combined with punching or drilling operations if needed. A CNC laser cutter (if available on-site) allows for even greater precision and more complex contours, including internal holes and markings.

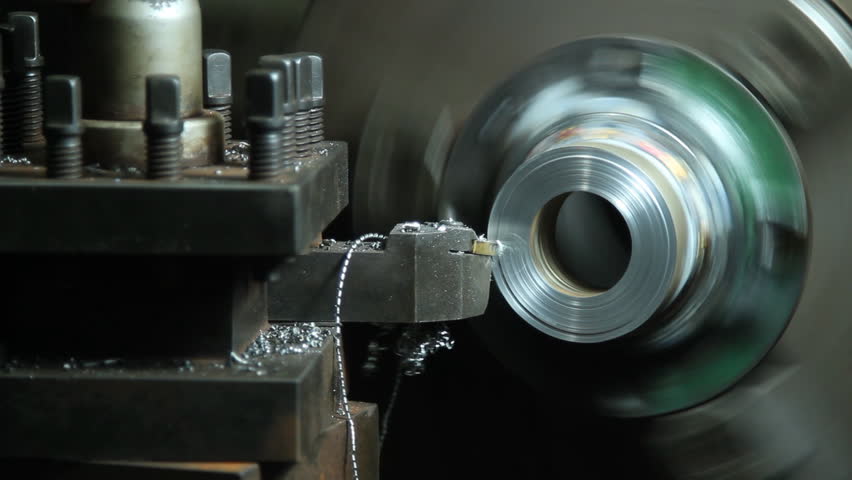

Turning – Manual (One-Off and Small-Series Precision Machining)

Manual turning is ideal for producing individual components, prototypes, and small batches that require flexibility, precision, and a fast response. We work with various materials – S235/S355 carbon steel, stainless steel (e.g., 1.4301), aluminum, copper, and plastics (e.g., POM, HDPE). Our equipment includes universal horizontal lathes capable of handling workpieces up to approximately 400 mm in diameter and up to 1000 mm in length (exact limits depend on the specific machine).

Typical operations:

Cylindrical and stepped turning

Tapered surfaces

Internal and external threading (M, G, UN)

Shaft ends, steps, grooves

Bore enlargements and fitting adjustments

All parts are machined according to technical drawings or customer samples. If needed, results are measured with calipers, micrometers, and tolerance standards (IT6–IT8 class). Manual turning remains efficient when part complexity doesn’t justify CNC setup time.

Painting

Surface protection and finishing of metal parts are performed using wet painting, preceded by standard surface preparation processes such as phosphating or sandblasting.